08.02.2017

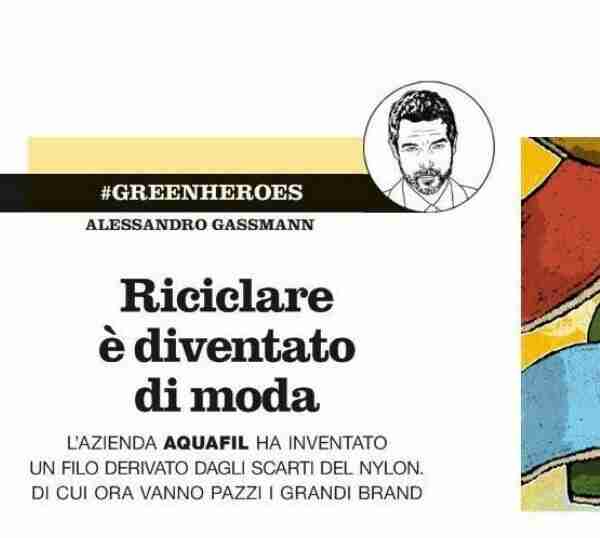

ECONYL®, la fibra sostenibile scelta da Levi’s e Gucci

E’ realizzato al 100% con materiali di scarto completamente rigenerati, destinati altrimenti a finire in discarica o nel mare. Per le capacità di rispettare l’ambiente, è stato scelto da alcuni dei più grandi brand del mondo

Dopo Levi Strauss Co. e Outerknown di Kelly Slater, anche il marchio Gucci ha deciso di adottare l’utilizzo di ECONYL di Aquafil . Un ingrediente tessile totalmente sostenibile, realizzato al 100% con materiali a fine vita in nylon, completamente rigenerati, in grado di diminuire i flussi di rifiuti destinati alle discariche o, peggio ancora, ai mari.