How Close are We to a Circular Economy in 2022? How Far Do We Have to Go?

The circular economy is a topic I discuss often. Not only is circularity a goal for Aquafil through our ECONYL® regeneration system, it is also a personal passion of mine.

As much hope as I have for a world driven by circularity, I also recognize how much work we have ahead of us in order to achieve it. To ask what must be done to transition from a linear to a circular economy would be overwhelming on a global level. What I can do is reflect on how the carpet manufacturing industry has worked toward circularity, and the steps ahead to fully realize a circular economy.

Image © Ellen MacArthur Foundation

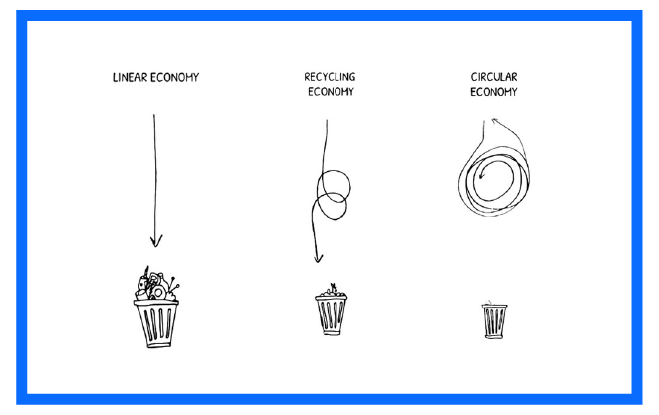

What is a Circular Economy?

With a circular economy, you must design or engineer products with the end in mind. This starts from the very beginning of the process with selecting ingredients that last longer, are reusable and repairable then finally recyclable.

You also need to design a way to eventually take back the products and renew the ingredients for reuse, closing the gap between where the product’s life ends and processing for creating new ingredients begins. In this way, there is no end of life for the ingredient—it never becomes waste.

Carpet Manufacturers Must Work Toward Circularity

The carpet manufacturing industry is a major contributor of energy depletion and waste. Because the ingredients to make nylon-based carpets are produced from extracted oil, new carpet can be one of the largest contributors of carbon emissions among interior finishes. In fact, using crude oil to make nylon yarn can be responsible for over 50% of its carbon footprint.

Carpets also have a relatively short lifespan, so they are regularly replaced in homes and offices, rapidly filling up landfills. Discarded fabrics made with nylon can take up to forty years to decompose. Three to four years in your home for several decades in a landfill? We can do better. We must do better.

Changing the Status Quo

Unfortunately, I have to tell you we are just at the beginning of our journey toward circularity. It will be a rewarding journey, but with over four billion pounds of carpet added to landfills in the United States every year, we still have a long way to go.

Consider our opportunity for change through these numbers: 12 billion square feet of new carpets and rugs are produced every year, 91% of carpeting is discarded in landfills, 4% is incinerated and only 5% is recycled. Even more disappointing is that of the 5% recycled carpeting, only one-fifth is repurposed back into carpet.

In addition to the room for improvement in recycling, greenwashing is one of the greatest challenges to achieving circularity in the carpet industry. Some carpet manufacturers may claim certain recycling rates or describe sustainable processes, but where is the accountability? Without regulation and enforcement, we will continue to see more talk than action.

Three Steps to Change the World

I always like to say that if you want to change the world you need three basic things: proper and effective legislation, tons of education and eco-design practices.

Encouraging carpet manufacturers to adopt a circular economy needs to start with legislative accountability. Regulations should include expectations to reduce waste and incentives to recycle and repurpose materials. California has led the way for these laws as the first state to establish a statewide carpet stewardship program, ensuring discarded carpets are sustainably repurposed. Not only has this increased recycling, it has also established new job opportunities.

Education is important for both the consumer and the manufacturer. We need pressure from consumers to increase the demand for more sustainable carpet manufacturing and need manufacturers to serve as role models for circularity by establishing eco-friendly practices.

Finally, eco-design practices must be considered at every stage of design, not just recyclability. If eco-design is not initiated from ingredient selection, there can be no circularity.

Aquafil’s Leap of Faith

I was inspired to lead Aquafil’s charge toward a circular economy by the fact that it’s a matter of do or die. If we do not change the way we are making products, especially as an energy-intensive nylon producer, it’s just a matter of when, not if, we face environmental limitations.

The process started with myself. I educated myself, altered my perspective, then took a leap of faith in changing the way our company’s leaders approached the industry. From there, we have worked to evolve as much of our value chain as possible.

The transition was a challenge, yes. But now Aquafil is able to produce recycled nylon 100% coming from waste through our ECONYL® brand. Our carpet recycling facilities in the U.S. process up to 36 million pounds of carpet annually, breaking old carpets down into three components which can all be repurposed and reused. For every 10,000 tons of ECONYL® raw material, we are able to save 70,000 barrels of crude oil and avoid 65,100 tons of carbon emissions.

The Power is in Our Hands

Imagine the impact if Aquafil is able to recycle even more carpets, and if more manufacturers would use recycled nylon. We have a long way to go, but I have hope for the day we achieve a circular economy.

Unfortunately, hope is not enough. But we do have power. Through our actions to educate, fight for legislation and use our purchasing power to make a statement, I do believe circularity can be within reach.

Author: Giulio Bonazzi, Chairman & CEO, Aquafil Group