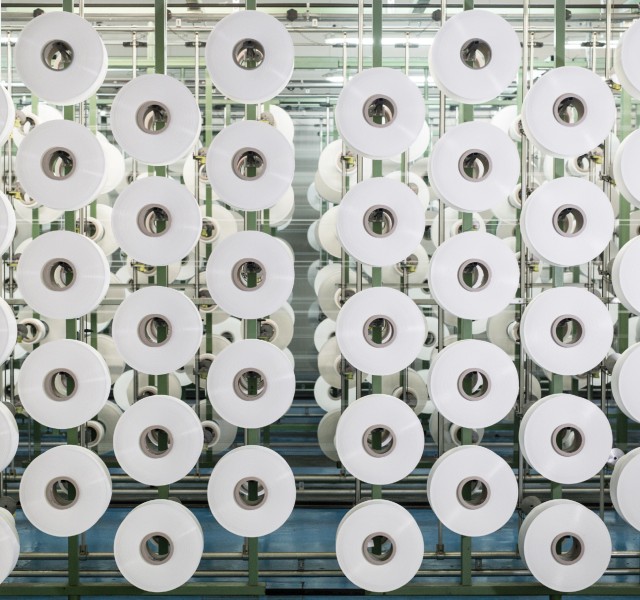

Yarn for Garments

Thanks to its long experience in the sector and its production of ECONYL® regenerated nylon, Aquafil has won an important share of the textile market as a major supplier of Italian and international apparel and sportswear brands.

In the textile fibers area, we are recently studying:

- the effects of UV rays applied to textile fibers;

- the opportunity to regenerate end-of-life textile products.

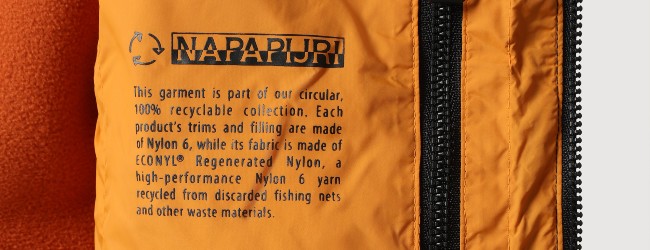

Aquafil has been strengthening its cooperation with key players that share its same vision for a sustainable future, driven by the willingness to change the world one product at a time. Over the years, great results have been achieved with partners such as Napapijri and Mammut.

ECONYL® yarn offers the same quality and performance as traditional Nylon 6, but with outstanding environmental benefits, as it is produced from nylon waste and is 100% regenerated.

The ECONYL® brand vision is to make the world a better place by pioneering closed-loop regeneration processes and delivering sustainable solutions.

Lightweight, insulating, breathable: Dryarn® is the athletes’ best performance enhancer.

Case studies

In addition, the company has already started a take-back program, in which after two years consumers will be able to return their jackets to the shop. They will then be completely reprocessed, as they are made of a monomaterial that can be reprocessed over and over again.

Thus was born the pilot project “Close the Loop”, which aims to give a second life to mountaineering ropes at the end of their life. Through a collection system set up for the purpose, the ropes are sent to Aquafil and reprocessed along with other pre- and post-consumer waste to produce ECONYL® yarn. Finally, to close the circle, Mammut has created T-shirts made of 100% ECONYL® yarn. Over three months of the project’s existence, approximately 750 kg of rope has been collected.

The project Re-Nylon is the result of the partnership between Prada and Aquafil, which has converted all standard nylon used by Prada into ECONYL® nylon.

To showcase the cutting-edge processes behind the Re-Nylon initiative, National Geographic, Prada’s Storytelling Partner, has produced “What We Carry”, a short video series that take viewers through a remarkable journey across the supply chain of these unique project.

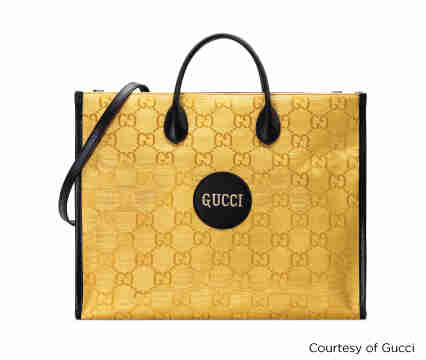

Gucci Off The Grid is an initiative created to support the House’s vision for circular production. Designed for those mindful of their environmental impact, Gucci Off The Grid uses recycled, organic, bio-based, and sustainably sourced materials, including ECONYL® nylon.

Gucci Off The Grid has been conceived to enhance respect for, and responsibility towards, the environment.

FT Dryarn® Warm is a men’s jacket with an ultra-lightweight and breathable baselayer that fits the body closely, supporting movement and ensuring the best possible comfort. Dryarn®, used in the weave of the fabric, manages heat to perfection, keeping the body warm and dry throughout the day and wicking the sweat produced during physical exercise to the outside of the garment.

Thanks to the bacteriostatic and dermatologically tested properties of Dryarn®, the Dynafit jacket is the ideal baselayer for all athletes who love outdoor sports even in adverse climatic conditions.

Dryarn® ensures maximum breathability and natural thermoregulation in all climatic conditions, protecting the body from major temperature swings, maintaining constant temperature and wicking sweat to the outside, always leaving the skin dry and protected from rubbing and unpleasant odors.

Montura garments made with Dryarn® are extremely hard-wearing and easy to care for. They are also bacteriostatic and dermatologically tested, ideal for use in direct contact with the skin.