The Forever Cost of Materials: How to Identify Quality, Cost-Effective Ingredients

We need to rethink the way we view the cost of materials.

Each material used in a design comes with an obvious economic cost, but there is also an environmental cost and the cost of disposal at the end of the product’s life. Inexpensive materials at the start may end up costing the planet a lot.

When creating a product, designers should consider materials that are durable, reusable, require less (or no) resource extraction and produce less microplastics for a lower overall cost.

How Much Do Your Materials Cost?

To make a complete assessment of the cost of a product, we would have to evaluate its entire life cycle: from the production of raw materials to how the product is disposed of, and all aspects of production, use and maintenance in between.

First, consider the direct costs. Costs that are related to more functional aspects, like the monetary cost of raw materials and production. This is where most designers and manufacturers may hesitate about investing in sustainable materials, which they may deem too expensive.

Now we consider the indirect costs: the impact of a product that gets thrown in a landfill, the reduction of resource availability and depleting fossil fuels, the dispersion of microplastics and general pollution. These hidden costs may be easy to ignore now, but will be paid heavily by generations to come.

After adding up all of these costs, it becomes immediately apparent that designing a product based on the principles of circularity – where materials are not only recycled, but also recyclable; where the life of the product is not only extended, but made almost infinite – would be the most cost-effective overall.

What Makes a Material Cost-Effective?

In addition to the economic costs of raw materials and production, a conscious designer will also consider the longevity and impact of their product in order to select cost-effective materials, asking themselves:

- Is this durable?

- Is this repairable?

- Can this be reused?

- Can this be easily dismantled and recycled?

- Does this release excessive amounts of microplastics?

Materials that are more durable and resilient also happen to produce less microplastics. ISO recently released the new standard method: ISO 4484-2:2023. Aquafil, STIIMA of CNR Biella and the Textile Commission of UNI CT 046 developed this methodology for the standard determination of microplastics released from textile sectors. Thanks to this methodology, it will be easier to identify and quantify the different effects of factors affecting the release of microplastics from textiles.

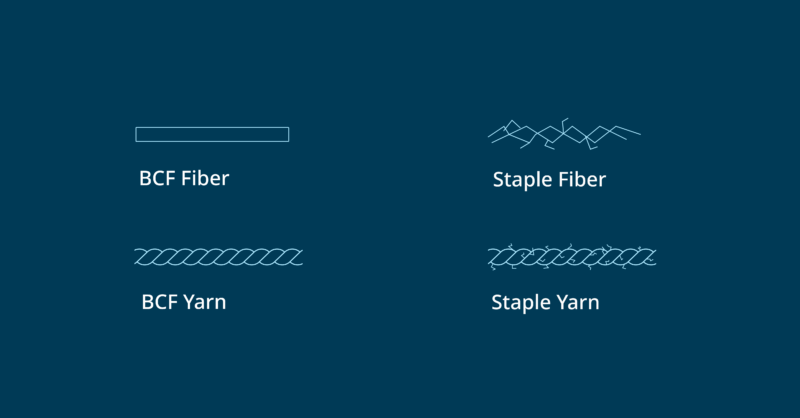

The method provides a way to measure the release of microplastics and will finally allow us to demonstrate what we might theoretically expect. That is, that a material that is more brittle and constructed with a discontinuous spinning technique, such as a staple fiber, can release more microplastics than another product that is more resilient and made with continuous fiber.

In general, the more microplastics released by a material, the more it costs. Microplastics influence both direct costs (the product degrades and needs to be replaced, limiting its life cycle) and indirect costs (the microscopic particles can negatively impact the plant and our bodies if ingested).

Can Lower Cost Still Mean High Quality?

ECONYLⓇ nylon proves that a cost-effective material (considering direct and indirect costs) can also be a high-quality ingredient.

By creating products with ECONYLⓇ nylon, designers can:

- Limit their environmental impact, since ECONYLⓇ nylon is made of nylon waste instead of fossil fuels, reducing its carbon footprint

- Create products that last, since nylon is a durable, high performing ingredient – and ECONYLⓇ nylon has the same characteristics as standard nylon

- Reduce waste, since ECONYLⓇ nylon can be recycled and regenerated an infinite amount of times, contributing to a circular economy

- Minimize the release of microplastics, since ECONYLⓇ nylon is spun into bulk continuous fibers, which has been proven to be more resilient than a lot of other fibers

Reducing the Cost of Materials, One Choice at a Time

Designers have the opportunity to reduce or even eliminate the “forever” cost of materials to our planet through one simple choice: the ingredients they use. When conscious designers consider not only the economic costs of their materials, but also the environmental and future costs, they are more likely to choose ingredients that are more cost-effective overall. Hopefully, if more designers choose more innovative materials like ECONYLⓇ nylon, future generations will not have to pay as much for our mistakes.

Author: Tiziano Battistini, Innovation Research & Development Coordinator